I have always used a simple Z splice. I make mine about 3 1/2" long so 4" of handle leather will cover it up completely. I know, I can hear the nay sayers now , "that is not enough gluing surface area, it will come apart" or "better pin that splice with a dowel or it will come apart". After around 100 splices like this I can assure you, if you use urac, this baby isn't coming apart. I even use this spice for simi bendy handle bows.

I draw the splice out on a legal pad, cut it out and glue it to the billet with Elmer's white glue, being careful to align the center of the splice with the center line on the billet.

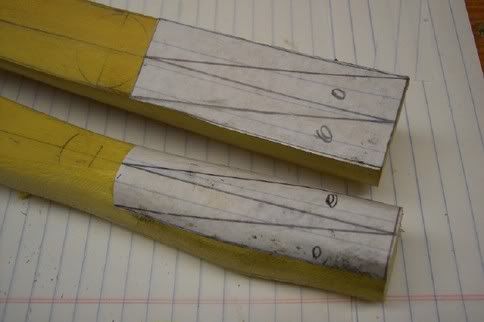

In this picture I am replacing a broken limb on bow. As you can see the glued on splice pattern conforms to the finished bow limb and will be cut out this way.

Even after cutting this type of splice you will have to make adjustments to the fit to get everything to slide together, a little sanding here or filing there and it WILL go together.

One thing that make splice cutting easy is to flatten the belly side of your billet prior to running it through a band saw.

I flatten the belly, lay it on may band saw table and sight down it. I adjust the flat belly to turn any slight twist up to the crown of the bow. I may add twist in the handle by flattening the belly at an angle section to remove twist in the working limb. Like I said I sight down the billet and select the position to correct as many alignment flaws as I can with my splice angle. I know, clear as mud......